Unveiling the Magic of Air Fittings: The Unsung Heroes of Modern Mechanics

Date: 2025-11-24 Categories: Blogs Views: 142

Excerpt:

Delve into the fascinating world of air fittings and discover how these small but vital components keep the wheels of industry turning smoothly. From their versatile uses to innovative designs, explore the importance of air fittings in everyday life.

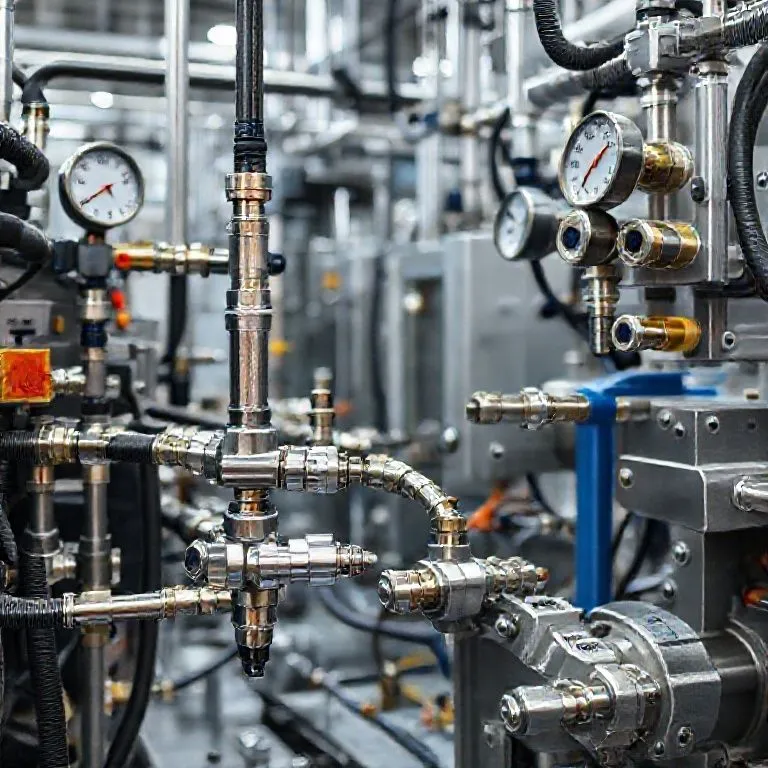

magine a world without compressed air — no pneumatic tools humming away in factories, no automatic doors sliding open effortlessly, no precision-controlled machinery performing intricate tasks with ease. It might seem like a stretch to imagine daily life without these unseen forces working behind the scenes. Yet, at the heart of this silent symphony are tiny components called air fittings — the unsung heroes ensuring every connection is airtight, secure, and ready to deliver.

What Are Air Fittings, Anyway?

Air fittings are specialized connectors that join sections of hoses, pipes, or tubes within pneumatic systems. Think of them as the versatile joints and adapters that help route compressed air from the source to various tools or machinery. Despite their small size, their role in maintaining a sealed pathway cannot be overstated; after all, air fittings are the gatekeepers of pressure integrity.

They come in several designs, each tailored for specific functions and environments, including straight connectors, elbows, tees, couplers, and valves. Whether for a delicate automotive assembly line or a high-powered industrial plant, choosing the right fitting ensures smooth operation and safety.

The Range of Uses in Our Everyday Environment

You might think air fittings are only relevant in factories or workshops, but they're woven into many aspects of daily life. For instance, high-quality air fittings enable compact, portable air compressors that homeowners use for cleaning or inflating tires. In hospitals, pneumatic tubes and medical devices rely on precision fittings to deliver gases securely and safely.

In automotive shops, technicians depend on a suite of fittings to power impact guns, tire inflators, and spray equipment. Even in large-scale construction, air fittings help operate jackhammers, drills, and pneumatic saws, making challenging jobs more manageable. Remote-controlled drones and robotic arms also leverage miniature air fittings in their pneumatic systems to achieve exact movements.

Types of Air Fittings: A World of Choices

The variety of air fittings available is as broad as their applications. Here’s a quick overview of the main types:

Push-to-Connect Fittings: Designed for ease of use, these fittings allow quick and reliable connection simply by pushing the hose into place. They are perfect for temporary setups or environments requiring frequent disassembly.

Threaded Fittings: These fittings feature screw threads that enable a tight, screw-in connection. They are often used for permanent setups or high-pressure applications, offering stability and durability.

Quick-Release Couplings: Known for their convenience, they facilitate rapid connection and disconnection without tools. Commonly used in mobile pneumatic tools, they prevent accidental disconnections during operation.

Elbow and Tee Fittings: To navigate tight spaces or split airflow into multiple directions, these fittings redirect or branch the airflow seamlessly.

Reducer and Adapter Fittings: When connecting hoses or pipes of different sizes or types, reducers and adapters bridge the gap, ensuring a smooth transition.

Materials Matter: Choosing the Right Fitting

Material selection is key to the longevity and performance of air fittings. Common options include brass, stainless steel, plastic, and aluminum. Brass fittings are prized for their corrosion resistance and strength, making them suitable for most industrial scenarios. Stainless steel offers excellent durability, especially in harsh environments.

Plastic fittings, often made from durable polymers like polypropylene or nylon, provide lightweight and cost-effective solutions for less demanding applications. Aluminum fittings strike a balance, offering corrosion resistance and weight savings.

The Importance of Proper Installation and Maintenance

Even the most well-designed air fittings can fail if not handled properly. Ensuring a snug, leak-free connection involves checking that fittings are tightened but not over-tightened, which could deform threads or crack materials. Regular inspection for signs of wear, corrosion, or damage keeps the system running smoothly.

Leak detection is a simple but vital task. Using soapy water or specialized leak detection sprays on fittings can reveal small leaks that, over time, can compromise system efficiency and energy consumption.

Innovations in Air Fittings: Brightening the Future

The field of air fittings continues to evolve with innovations focused on safety, efficiency, and environmental sustainability. Quick-connect fittings are becoming more ergonomic and reliable, reducing setup times and user fatigue. Some designs incorporate anti-corrosion coatings or use biodegradable materials, reflecting environmental concerns.

Smart fittings with sensors that monitor pressure or detect leaks are on the horizon, promising smarter, more responsive pneumatic systems. Such advancements represent the ongoing quest to make compressed air systems not just more efficient but also more environmentally friendly.

A Small Component with a Big Impact

Air fittings might be small, but their influence is profound. They facilitate everything from delicate scientific instruments to massive manufacturing plants. They embody the blend of simplicity and complexity — straightforward in function, yet vital in purpose.

In the next part, we’ll explore how to select the right air fittings for your needs, the common pitfalls to avoid, and some practical tips to keep your pneumatic systems running flawlessly. From DIY enthusiasts to seasoned engineers, understanding these connectors will help you appreciate the critical role they play in powering our modern world.